ŠKODA 90 YEARS ON THE PRODUCTION LINE

The car collection process is a wonderful show from individual components, which have a clearly defined place for each machine. Cars were first assembled and were very expensive. In the first decades of the 20th century, manufacturers began looking for ways to make cars cheaper to spread the customer network.

Then and now: Body parts warehouse

Some thought the solution was to compose some low cost engineering design. In the end, however, the key was in one of the basic rules of economics: high yields make cheaper production. The answer was then, the production of conveyor belts, and Mladá Boleslav plant launched its first conveyor belt system 90 years ago.

Compared to today, the number of cars sold in the Czech Republic was very small today. For example, in the first three months of 1925, the year Laurin & Clement was part of the Skoda Plaza Group, among those sold in Prague, 17 Lorraine & Cleiz, 59 Pargas and 31 Tatra. Named selling brands after. At the end of 1925, according to the research report of the University of Massiric in Brno, there were 12,580 passenger registered cars in the Czech Republic. Today the figure is more than 5.6 million.

Keep production of the car as low as possible except because of the government's defense policy that foreign car imports are limited in Czechia. But Vlavv Klement, one of the founders of the company, knows how to grow a business. He followed international competitors very carefully, seeing that some people started using the conveyor belt. To do this, L&K needs significant investment, which is one of the reasons that the brand comes with ŠKODA.

The first step towards the realization of the series was a new body shop of four stores in Mladá Boleslav. Completed in 1926, the new center consists of an underground warehouse, a production of carpentry parts on the ground floor and a remodeling and remodeling work on the first floor, while on the second floor the wooden components are assembled to form all parts of the cars, which are then painted on the third floor.

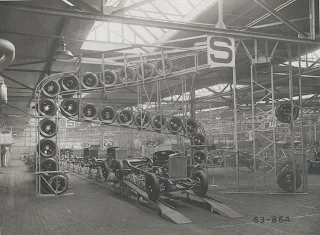

This system, however, provides a taste of conveyor belt potential. In April 1928, the Company laid the groundwork for another building. Called Mechanics, this unit is 200 meters long and 130 meters wide. Construction was completed shortly before the end of 1928 and the facility was put into service in 1929. The building was used to assemble the chassis and build engines and deliveries. Two other buildings were continued: the body was made of four body panels transported across the bridge to the Meccanica Temple, where the engine and chassis were erected. This means that conveyors use the production they have achieved, making ŠKODA the first automobile manufacturer in the world to produce automobiles and industrial vehicles. This is an advantage for all local competitors and the company is implementing rapid success in the market. In 1930, the production line was capable of producing 25 cars per day. ŠKODA has made significant changes and has started a three-day operation to increase daily power to 85 vehicles. The foundations of modernity were set up 90 years ago.

Then and now: Dispatch to customers

Comments

Post a Comment